This past autumn I was commissioned to build a chair by a student in the Chair Design class I was co-teaching with Jeff Miller at the Center for Furniture Craftsmanship. During the brainstorming / model making / getting creative energy flowing exercise the student (Jed) came up with a captivating model by "simply" folding paper together into the form of a chair.

I wish I had decent pictures of the model, but let me tell you, Jeff and I were both immediately drawn to this concept and the potential it had. After a day or two of head scratching our collective brain power was getting pretty mushy, Jed's chair was redesigned capturing some of the elegant lines the model had into a design Jeff, Jed and I were confident in Jed being able to build in just over a weeks time. By the end of the class Jed had created a striking, sit able chair, but he longed to see that original folded together model come to life. Jed commissioned me to make the original design, the endeavour took on a new life.

I knew I had gotten myself into a pretty hefty challenge, but let me tell you, I greatly underestimated what lay ahead. Fold some veneer here, fold some veneer there, voila, chair. I knew it was going to be labour intensive, but what I did not anticipate was the mathematician level of trigonometry / master origami problem that lay before me.

I started in my sketchbook (like always) and came up with a few reiterations of the chair I was content with and started trying to decipher just how to build one of them. After more head scratching I realized I was chasing the wrong concept altogether, and that in reality I wasn't pleased with any of the three concepts I was initially working on. I was trying to merge Jed's original model, his finished redesigned chair and something I thought would be comfortable into a pretty little package. I had ended up in a place with a chair that lacked a cohesive look and feel, I reached out to Jed wanting to discuss the project with him. Jed had no interest in seeing and adding input on the designs, he wanted me to find the right design for myself, to look past the hangups and let my voice be heard. It was a deflating and empowering moment all at once. I took a long walk, enjoyed some fresh air, and realized I needed to go back to the start. I got out the paper, and for what seemed like days folded together both model sized and full sized chairs. From here my current concept was born. I ended up straying a bit from the original model Jed had folded together back in September, but have found a direction I believe will lead to a very unified, refined looking piece.

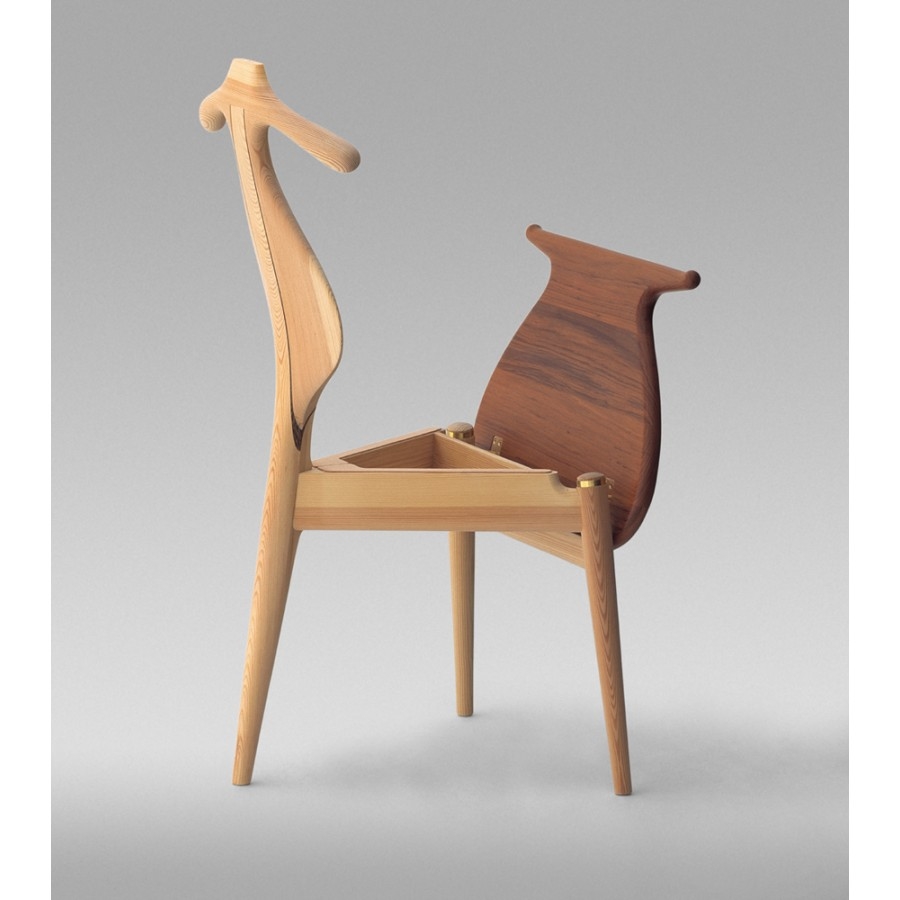

The plan is to make the chair out of just two parts, seems easy enough right? The first part will be a bent panel that makes up the back rest, arm rests, and back legs of the chair. The second part will be a bent panel that makes up the front legs, seat, and another set of back legs. The two panels will then be joined (glued and bolted) up the back leg. Both panels will be pressed out of commercial veneer with alternating grain direction to essential be shop made plywood, this way it will be strong and stable. There will be relief cuts in the veneer to allow for the panels to split apart (top of the back rest and front of the seat) where the panels change the plane they are being bent on.

Pictured below are a few (of what seems like hundreds at this point) of my mockups. They are cut from paper, cardboard, and one version made out of plywood to get something rigid enough to take angles from and sit in to work through ergonomics.

I know it doesn't seem like much yet, but stay tuned, this will be a learning intensive journey for everyone involved.